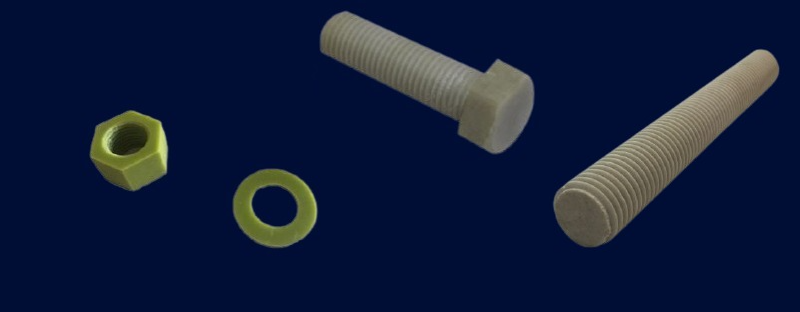

FRP Fasteners

FRP fasteners are employed in technical sectors where electrical, chemical, and thermal properties are critical. Glass fibre reinforced epoxy or polyester resin systems with particular additives and a unique structure are used to make our offered fasteners. Explore our website to discover our diverse range of other FRP products.

FRP fasteners have the following advantages over steel fastening:

- a lot lighter

- Insulating both electrically and thermally

- Durable and Corrosion resistant

- Defiant in the face of adversity

Properties of FRP Fasteners

- ELECTRICAL PROPERTIES: FRP fasteners are non-magnetic and electrically insulating. Furthermore, partial discharge is free to large electric field strengths and is particularly non-tracking. They’re great for transformers, electrical engineering, high-frequency switching, and electrostatic powder coating.

- CHEMICAL PROPERTIES: FRP fasteners are particularly resistant to strong fluids and gases, as well as transformer oil and dielectric liquids. They are also UV and weather resistant.

- THERMAL PROPERTIES: When compared to steel (15-58 W/mk), frp threaded rods, bolts, and nuts have a very low thermal conductivity of 0.3 W/mk, which puts them on par with mineral wool, which is used as insulation in construction. They’re perfect for use in refrigeration, HVAC, and other applications where thermal bridges are a concern.

- COMPOSITE FASTENERS ARE LIGHTWEIGHT: Composite fasteners have a density of 1.9 t 2 g/cm3 and hence weigh about a quarter of the weight of steel. They’re ideal for applications where weight reduction is critical, such as vehicle construction or the fabrication of wind turbine nacelles.

- HIGH TENSILE STRENGTH: Threaded rods manufactured of thermoplastics, such as polyamide frp, offer a six-fold higher tensile strength than threaded rods made of metal.

Fields of application:

- Flue gas desulphurization plant

- Onshore / offshore engineering

- Chemical plants

- Hydraulic engineering, sewage treatment plants, desalination of seawater

- Transformers, dry-type and oil immersed

- Generators

- Switchgears

- Instrument construction, High-frequency Systems

- Traffic engineering

- Refrigeration and air conditioning

- Cable trays

- Electrostatic powder coating

- Electroplating plants